quality in every step of the way

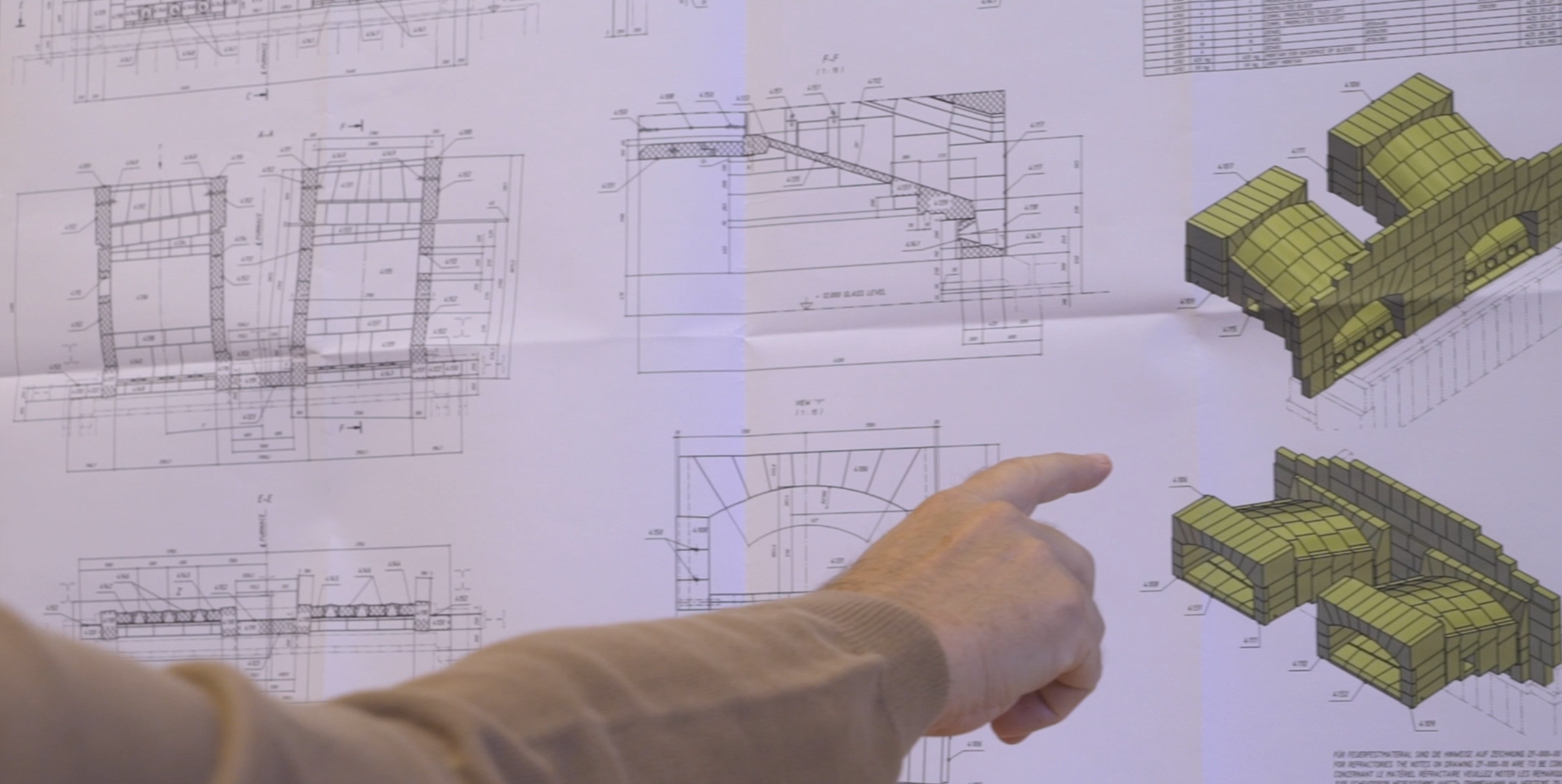

1. Moulding plate manufacturing

2. Preperation of moulds

Computer aided control of order specifications.

Control of the mould’s geometrical accuracy.

3. melting and casting

The material fused in eletric arc furnaces is cast into moulds.

4. cooling

After the mould is removed, the cooling period starts.

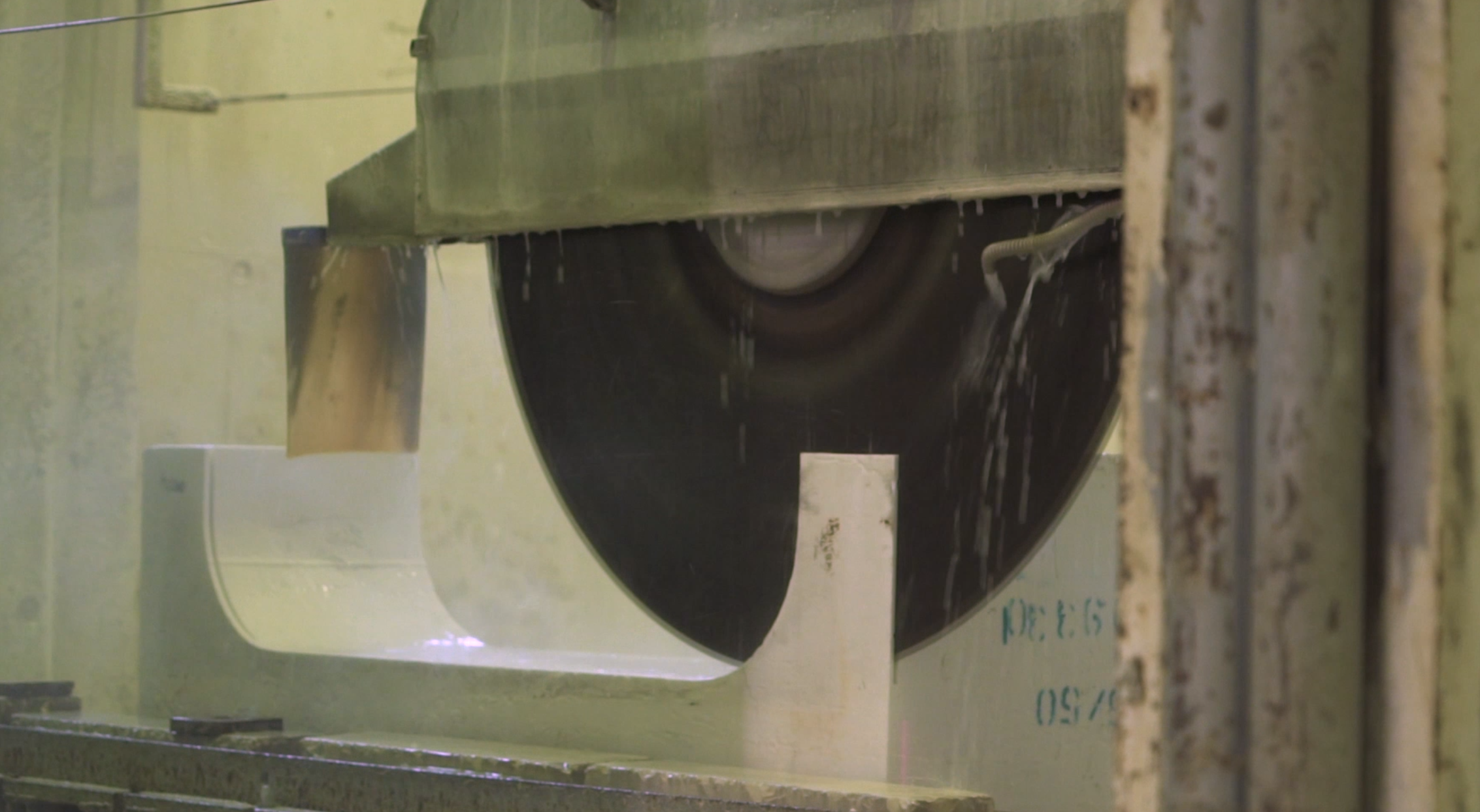

5. cleaning and cutting

Blocks are also checked for their physical parameters.

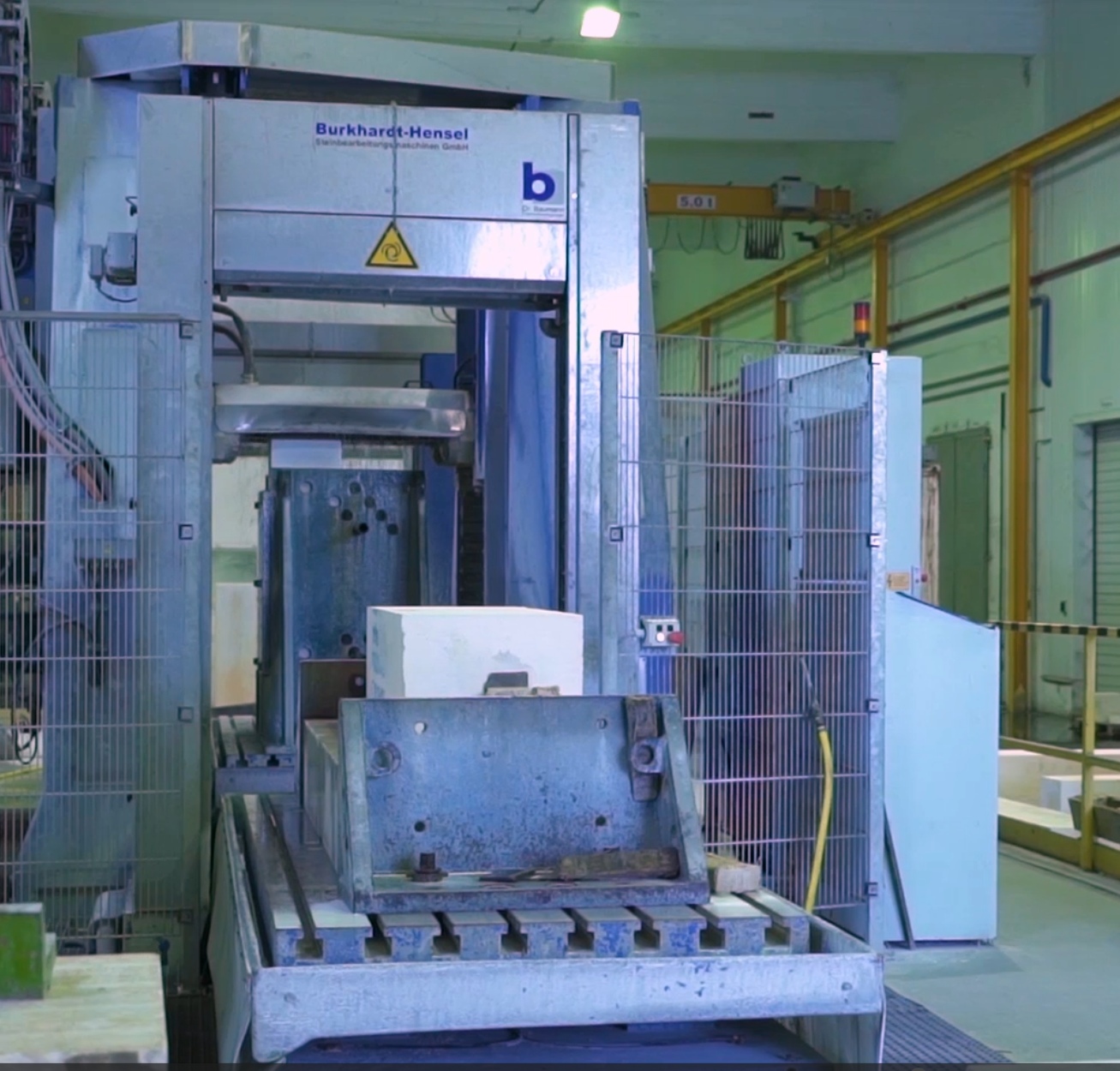

6. Grinding

After void control, the blocks go through the grinding process to ensure a fitting surface.

7. pre-assembly

All blocks undergo a final inspection before the pre-assembly, where customers can inspect the end product.

8. packing, storing, shipping

Only after everything is in order and the customers are happy with the product, are the blocks carefully packaged and made ready for delivery.