discover the fused cast refractories product range

At Motim, we understand that having a variety of casting methods and materials is essential to meet the diverse needs of our customers. That's why we offer a wide selection for you to choose from, ensuring that you can find the perfect fit for your project. Whether you require the best quality materials for high temperature zones or more cost efficient ones for low exposure zones, we have you covered. With our range of options, you can select the method and material that aligns best with your specifications, guaranteeing high-quality results every time.

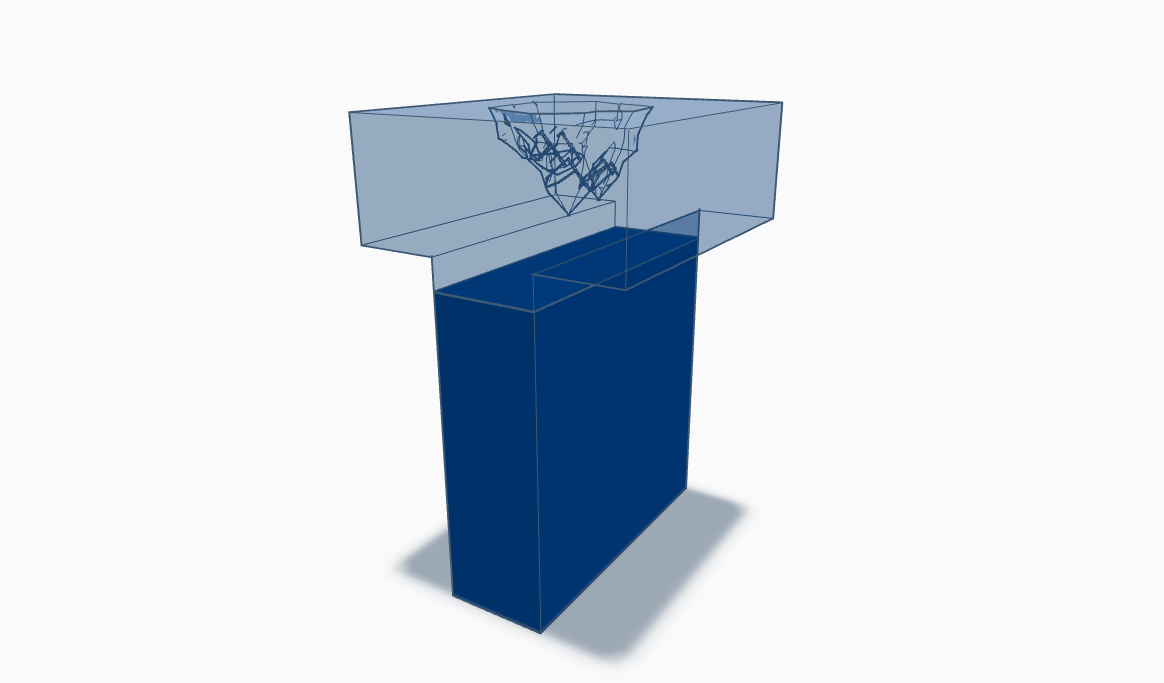

MOTIM carefully manages shrinkage cavities in fused cast refractory production to enhance block performance against wear. Korvisit and Zirkosit blocks are manufactured with various casting methods, offering solutions with reduced cavities. Non-destructive testing monitors cavity location and block solidity. A computer program compares radiation intensity values to determine block solidity, documented alongside cavity location according to quality standards.

our casting methods

-

Type: N

The shrinkage cavity is located in the middle of the side, opposite to the working face near to the surface.

-

Type: EL

The casting is made from the end of the block opposite to the metal line and the major shrinkage cavity is cut off.

-

Type: KLB/KLP/KLS

The part of the block containing the shrinkage cavity is cut off.

Materials and production methods

MOTIM introduced the original α-corundum type fused cast refractory in 1957. KORVISIT-AB is similar to KORVISIT-A, but features an αβ type crystal structure, ideal for lower temperature zones in glass melting furnaces. To meet the demands of modern high-capacity furnaces, MOTIM introduced AZS type fused cast refractory blocks in 1965, marketed under the name ZIRKOSIT. These blocks, containing α-corundum and baddeleyite, offer outstanding performance in low and high temperature applications, while silica and low alkali content enhance thermal shock resistance. Since 1986, ZIRKOSIT products are supplied in oxidized form, and MOTIM now offers three types of AZS refractories, allowing customers to select the most economical solution for their furnaces.

ZIRKOSIT-S32

32,6% zirconium-dioxide content

excellent result both in high and low temperature zones

long history of use in glass melting furnaces

recommended for:

Casting methods:

-

Recommended use: superstructure, working end, feeder channels and non-glass-contact-areas

-

Recommended use: superstructure, working end and feeder channels

-

Recommended use: bottom paving, side wall patching and joint cover blocks

ZIRKOSIT-M36

36,2% zirconium-dioxide content

better performance than S32 but more economical than Y41

recommended for:

side walls

superstructures

working ends

bottom paving

feeder channels

Casting methods:

-

Recommended use: superstructure, working end and feeder channels

-

Recommended use: side walls

-

Recommended use: side walls, corner blocks, bubbling blocks and weir blocks

-

Recommended use: bottom paving

-

Recommended use: bottom paving, side walls, superstructure and feeder channels

ZIRKOSIT-y41

41% zirconium-dioxide content

our highest zirconium-dioxide content AZS type fused cast refractory material

yields excellent results in most exposed parts of the glass melting furnace

recommended for:

weir

throat

side walls

corner blocks

electrode blocks

bubbling blocks

Casting methods:

-

Recommended use: superstructure, working end and feeder channels

-

Recommended use: side walls

-

Recommended use: throat, doghouse corner, side wall blocks, electrode blocks, bubbling blocks and weir blocks

-

Recommended use: bottom paving and patching tiles

-

Recommended use: doghouse, thoat, weir, bubbling blocks and electrode blocks

Korivisit-A

reputed refractory and wear resistant lining of reheating furnaces

resistant to mechanical wear in high temperature conditions

recommended for:

skid rails

soaking zone bottom of heavy duty pusher-type furnaces reheating ingots

lining exit chutes in walking beam furnaces

Casting methods:

Korvisit-A N

Korivisit-AB

Alpha-Beta-type fused cast refractory material

superior corrosion resistance and low blister potential

ideal product for the lower temperature zones of the glass melting furnaces

recommended for:

side walls

bottom paving of working ends

feeder channels

certain parts of superstructures

drawing chambers of sheet glass furnaces

Casting methods:

-

Recommended use: side walls, bottom paving of working ends, feeder channels, certain parts of the superstructure

-

Recommended use: side walls bottom paving of working ends, feeder channels, drawing chambers of sheet glass furnaces and superstructures (from the 4th burner port)

-

Recommended use: bottom paving

Korivisit-B

Beta-Alumina-type fused cast refractory material

very strong resistance to alkaline vapor and thermal shock at elevated temperature

recommended for:

superstructures

Casting methods:

-

Recommended use: superstructures

-

Recommended use: superstructures

Together with our fused cast refractory blocks, we also provide unshaped refractories. For the bedding mixes below the paving we use hydraulic bond monolithic mixes called ZIRMOTIM and ALMOTIM. Both of our products are available in different grain sizes ranging from up to 5 mm to 0.5 mm. Such bedding mixes act as leveling courses to ensure a stable setting for the blocks and reduces the possiblity of glass penetration.

unshaped refractories

Almotim

AMOTIM concretes are made out of fused alumina grains

we offer it in combination with Korvisit fused cast alumina shapes in the working end and feeder channels

Recommended use:

ALMOTIM-5 used directly on the subpaving

ALMOTIM-2 is the bedding layer for fused cast tiles and feeder shapes

zirmotim

made out of fused AZS grains

applied with the bottom paving tiles

acts as safety layer minimizin glass infiltration

helps prevent glass flow under the tiles

the different types have same chemical composition but varying grain size

Recommended use:

ZIRMOTIM-5 used directly on the subpaving

ZIRMOTIM-2 is the bedding layer for fused cast tiles

ZIRMOTIM-0,5 for filling the residual joints

hot repair mixes

chemically bonded

can be applied as a separation course between silica based materials and AZS type materials

for hot-repair of silica based materials